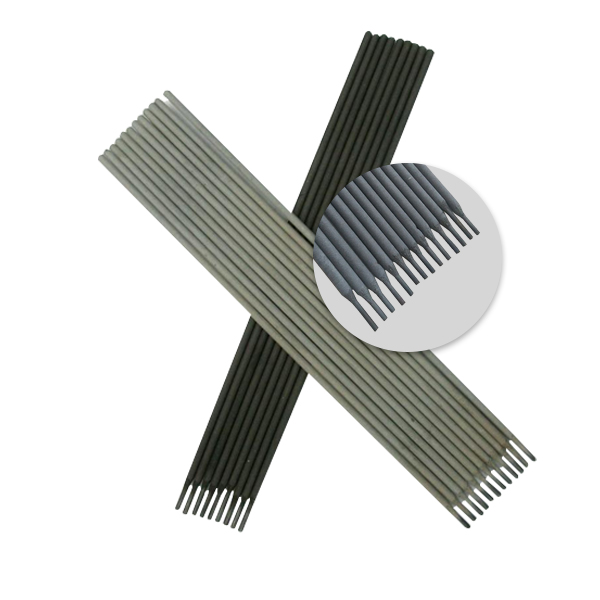

Vyuma vya Juu vya Carbon Mwongozo wa electrode E9818-G Utengenezaji wa soldering

COMPONET YA KIKEMIKALI:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T KANUNI | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| KANUNI ZA AWS | - | - | - | - | - | - | - | - | - | - |

| MFANO THAMANI | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

MALI YA MITAMBO:

| MALI | NGUVU YA MAVUNO(MPa) | NGUVU YA UPANUZI(MPa) | JOTO℃xh | THAMANI YA IMAPACT J/℃ | UREFU(%) | |||||

| GB/T KANUNI | - | - | - | - | - | |||||

| KANUNI ZA AWS | - | - | - | - | - | |||||

| MFANO THAMANI | 915 | 992 | - | 65/-20 | 16 | |||||

VIGEZO VINAVYOPENDEKEZWA VYA KUCHOMEZA:

| MAELEZO YA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| UMEME (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa yenye nguvu ya juu ya chini ya aina ya poda ya ferrohydrogen ya aloi ya chini ya elektrodi.

Arc imara, splash ndogo, uondoaji mzuri wa slag

Utendaji bora wa kulehemu wa kila mahali, uthabiti mzuri wa halijoto ya chini, ukinzani wa nyufa na ushupavu wa athari ya joto la chini.

COMPONET YA KIKEMIKALI:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T KANUNI | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| KANUNI ZA AWS | - | - | - | - | - | - | - | - | - | - |

| MFANO THAMANI | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

MALI YA MITAMBO:

| MALI | NGUVU YA MAVUNO(MPa) | NGUVU YA UPANUZI(MPa) | JOTO℃xh | THAMANI YA IMAPACT J/℃ | UREFU(%) | |||||

| GB/T KANUNI | - | - | - | - | - | |||||

| KANUNI ZA AWS | - | - | - | - | - | |||||

| MFANO THAMANI | 915 | 992 | - | 65/-20 | 16 | |||||

VIGEZO VINAVYOPENDEKEZWA VYA KUCHOMEZA:

| MAELEZO YA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| UMEME (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Andika ujumbe wako hapa na ututumie